It gives us great pleasure that you have decided to try out this system

on your bike. This kit is something that I spent many years working on it

stemmed from problems I was having with my Bike.† Which is a Yamaha RD350B 1984modell (1974 for

you guys). This isnít a big commercial product. Nor am I a big manufacturer.

Just a simple guy who likes to make things with his hands.

The kit as you see it now is a far cry from the early kits we shipped

years ago. We pride ourselves on the constant effort to improve the kit. The

separate CDI is the third major revision of our CDI kit. And we are actively

working on the forth and final revision for the same kit. Which will be a Digital

Programmable CDI with a LCD Speedo and RPM counter. Efforts are being made to

ensure that existing customers can upgrade to this digital CDI for a very reasonable

fee. As soon as its ready.

Contents:

Base Kit :

Brass

Coil Plate with Lighting / charging, source and pulsar coils

Magnetic

Drum.

Two New

Technology combo HT Ignition Coils with C.D.I OR Separate CDI and HT coils.

Rectifier

& Regulator

Options:

1. New Switch Cluster Left (Turn/PO/Hi-Lo/Horn

etc.)

2. Flasher (Required for Indicators, requires a

batt. to work)

3. 3x1 Instrument Cluster Bulb

Holder (high beam/neutral/turn)

4. Harness (Complete New Yamaha Harness,

everything just plugs in )

5. Ignition Switch with Two keys (For

R5/RD200/RD250/RD350 etc) Note mounting clamps may not match. But you

have to use our switch. You can switch the insides with the older switch

though.

6. Clutch Lever Yoke and Clutch Leaver.

7. Head Light Bulb holder (two types).

8. Indicator Buzzer (If available).

9. Fuse

Box for DC Bat.

Installing the Kit:

The install is

really quite simple. But its best to get it professionally installed.

1. First strip bare all the old stuff off your

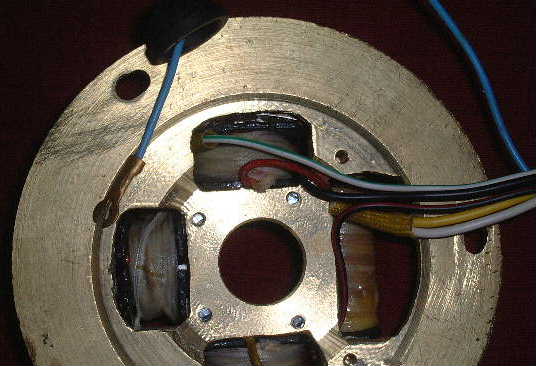

crank end. Like so:

2. Then Install the Brass Plate make sure the

pulsar is located at the

Also make sure to route the wires behind the plate so that they do not get crimped or crushed between the brass plate and engine. Like so

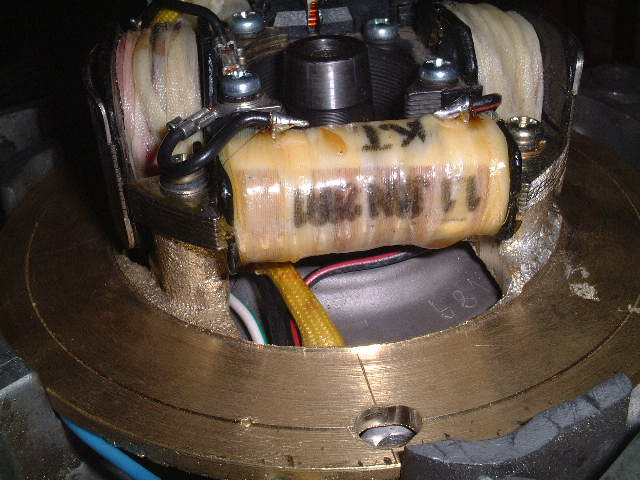

3. Then install the drum over the crank end.

Make sure to use the woodruff locating key. Make sure your key fits in the slot

the cam on the drum has. It should be a really tight fit. Route the blue

neutral switch wire from under the brass plate. Also check to make sure the

wires are not pinched between the plate and engine casing.

4. Now hook up the CDI harness to the two

bullet connectors. Coming off the brass coil plate. On is source power (Black

& Red) the other is pulsar (White blue) this is all thatís required to make

the bike run.†

5. Do not connect up the Black and white wire

on the CDI harness to anything till you have the bike running. This is the same

as the source power in and the only thing it should hook up to is a kill switch

by no means should it touch any DC voltage or join any other wire as this would

fry the CDI. Once you have the bike running the black&white wire on the CDI

harness can be hooked up to the main harness which has a b&w bullet

connector.

6. The HT Coils have a Green wire and a Black

and Red. Green is earth and black and red is power in. Make sure the HT Coils

are earthed to the frame of the bike by bolting them down tight scrape off any

paint so there is good metal to metal contact, between the metal part of the HT

coils and the body earth.

7. We repeat do not hook up anything else

except the CDI and HT coils till you get the bike running. Once its running.

You can start installing the other options.

Understanding the color codes:

Brass Coil Plate:

∑

Black+Red: Source power to HT Coils. (Bullet Female) 280Ohms / 12+ Volts a/c on

kick over. Connects to CDI harness.

∑

White + Green: Pulsar Signal to CDI (Bullet Female) 80

Ohms / 2 Volts a/c on kick over. Connects to CDI harness

∑

Yellow+Red: Source power Head Light & RR Unit (A/C) 1 Ohms

∑

White: Source power A/C to RR for Conversion to DC 1 Ohms

∑

Blue: To Neutral switch on White Triangular plastic

∑

Black:

Earth.

HT Coils:

Green: Earth must be grounded to chassis

connects to the 2 greens off CDI harness.

Black

& Red: Source power in.

Connects to CDI Harness.

CDI† Harness:

Green White: † Pulsar

signal (to Bras coil plate)

Black Red:†††††† Source power (to Brass Coil Plate)

3x Green: †††††† Earths one to Body 2 to HT Coils

2x Black Yellow: Source Power to HT

Coils

Black White:†† Same as source in only to be connected to

Ground to kill engine (Hooks up to a black and white wire on the Main Harness)

Integrated

CDI: These use 3 Y

Cables that are White, Red, and Black and white. These are used to split the

Source signal from brass plate and pulsar signal to the two HT/CDI units.

Rectifier

& Regulator:

Yellow+White: A/C

power for Head light.

White+Red:†††† ††††††††††† A/C in off coil plate

Red:†††††††††††††††††††††††††††† DC

out 13.5-14.5 Volts. Do not load without a batt. Hooked up.

Black or B&W ††††††††††† Earth.

We have labeled the complete harness. Simply

read and plug in required component.

FAQ

Kits where both CDI systems have been

supplied. Which do I use.

We recommend you use the newer separate CDI system and keep the combo units as a back up.

If you can get your hands on a Single HT coil with dual leads off a bike that came with a CDI like the RZ350 then this HT coil will give you the best performance.

Danger of blowing up CDI.

The CDI will be damaged if

HT Coils used with a CDI are totally different from HT coils that are designed to work with a Battery based system. Using performance coils designed to work with the Bat i.e. DC voltage will damage the CDI.

Please do this at least once. Click here for timing document.